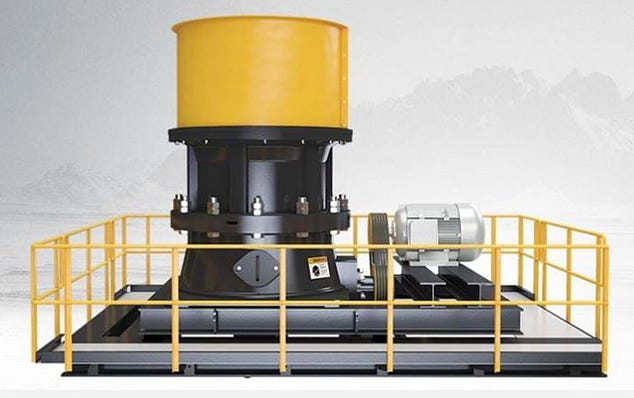

What is Cone Crusher?

What is Cone Crusher? What are the Samples?

Cone crushers are designed to crush hard and abrasive creek and quarry materials such as granite, basalt and andesite. It is used as secondary and tertiary crusher.

The working principle of cone crushers is to break the materials with the effect of compression, cutting and bending.

It offers low dust and abrasion rates as they break the material by compressing it.

Thanks to the long-wearing wear parts, the crushing process is longer lasting.

Cone Crushers, are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like iron, chrome, magnesite and copper ores.

The robust design and high-grade cast steel body cone crusher provide the strength and stability necessary for crushing extra-hard materials while ensuring low maintenance costs.

In addition, since the maintenance and repair operations can be done easily on the breaker, the operating costs are low.

Since crushing is done between conical surfaces, the crusher is also called “cone crusher”.

Very different in terms of size and structure, today

shapes are found.

There are two main types in general: “movable national” and “fixed national”.

Pivoting National Cone Crusher:

Depending on the lower extension of the main shaft and the way of moving the shaft, it can be long or short shaft, suspended from the bridge or with a bottom bearing.

In addition to the support bearing, a hydraulic lifting device can be found.

The main structural elements of the breaker are;

Body (lower and upper), Mouth collar and bridge

Hub and main shaft, Eccentric sleeve and bevel gear

Drive assembly, Concans and core linings

Broken goods trough, Adjusting device, Lubrication device

Fixed Shaft Cone Crusher:

The feature of this type of breaker is that the main shaft through which the hub passes is fixed and the hub makes an eccentric secretion around this fixed shaft. The amplitude of the epidemic always remains the same at various levels of the navel.

The main structural elements of the breaker are;

Body, Mouth collar and bridge

Hub and main shaft, Eccentric sleeve and bevel gear

Flanged sleeve, Drive assembly

Concans and primers, Adjusting device

Reference;

(2) Crushing plant — Wikipedia